Reception: +375 (2334) 3-80-00

Sales Department: +375 (2334) 3-85-85

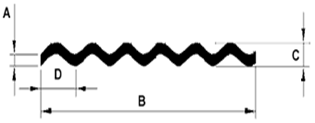

Steel fibers are pieces of steel wire from 0.30 to 1.1 mm in diameter and from 15 to 50 mm in length of ripple cross-section. A steel fiber is used for three-dimensional reinforcement of concrete and replaces steel mesh.

Advantages of fiber use:

- a significant increase of resistance to cracks and deflections;

- excellent adhesion to concrete;

- increase of impact strength;

- increase concrete water resistance ;

- improvement of shrinkage behavior;

- corners and edges strengthening;

- longer service life of constructions;

- easy to use.

ECONOMIC BENEFITS OF STEEL FIBER USE:

- reduction of coat thickness;

- decrease of labour cost;

- decrease of construction time;

- easy manual and machine laying.

“Tanis fiber” is produced according to TU RB 400518274.004-2009 from steel 70-85.

Type of anchor fiber:

FSV LV – a steel anchor fiber with brass-plated coating

FSV BV– a steel fiber with bronze coating

FSV PV - a steel fiber without any coating

Corrugation step width: 4-5 PCs

Corrugation height C – from 1.5 to +/-0.05.

|

Diameter of a fiber (A), mm |

Length of a fiber (B), mm |

|

0,3±0,05 |

15±5 |

|

0,4±0,05 |

20±5 |

|

0,5±0,05 |

25±5 |

|

0,6±0,05 |

30±5 |

|

0,7±0,05 |

35±5 |

|

0,9±0,05 |

50±5 |

|

1,0±0,05 |

50±5 |

|

1,1±0,05 |

50±5 |

Tensile strength for fibers from high carbon wire is not less than 2200 MPa (N/mm2).

Fiber is packaged in corrugated cardboard boxes per 20 kg or on pallets per 720 kg.

INSTRUCTIONS FOR FIBER USE

For making fiber-reinforced concrete it is used a traditional mix of sand, cement, coarse or fine aggregates and water to which a certain amount of fiber is added.

It is important to achieve a uniform distribution of fibers throughout the concrete matrix. The addition of fiber material should be made evenly and gradually — one-time loading as well as excessive stirring can lead to the compound homogeneity violation and so-called "hedgehogs"(plain surfaces without projecting parts) emergence.

Variants of compound making:

- Adding fiber into a truck mixer directly on the construction site, mixing for 3-5 minutes at maximum speed, and unloading;

- Adding fiber directly on a plaster and concrete unit when making a concrete compound.

Consumption of fiber is determined by concrete characteristic requirements and it normally is:

- industrial floors - 20-40 kg/m3;

- frameworks of residential buildings - 25-50 kg/m3;

- outer constructions without protective coating - 40-120 kg/m3;

- transport constructions 50-100 kg/cubic meter.

|

Floor thickness |

Advisable diameter of fiber |

|

45-70 mm |

0,3-0,4 mm |

|

70-120 mm |

0,5-0,6 mm |

|

120 and more |

0,7-1,1 mm |